UK – The Code For Sustainable Homes

The Government’s objective for the Code is that it becomes the single national standard for the design and construction of homes, and that it drives a step-change in sustainable home building practice.

- The aim to make the system of gaining a Code assessment as simple, transparent and rigorous as possible, a process that inspires confidence in Code assessors, home builders, product manufacturers and, crucially, consumers.

- The Code supersedes EcoHomes and with it, it lifts the standards required for energy and water consumption.

The Government has indicated its intention to use the code as the basis of future Building Regulations Part L (1A) changes, proposing it as a route map for new homes to become net-Zero Carbon by 2016.

The Code defines 6 Levels of environmental sustainability:

- Level 1 is set just above current 2006 Building Regulations.

- Level 6 is ‘net-Zero Carbon’ for homes in use, including appliance and occupant energy use.

An increasing proportion of credits are needed to satisfy each level, of which a mandatory proportion are energy and water, reflecting the growing importance of climate change and potable water availability.

Technology to Generate Renewable Energy

Biomass boiler

The boiler provides hot water and space heating in winter, fuelled by wood pellets. It is located in the utility room to provide a dedicated drying area, as an alternative to the (electricity sapping) tumble dryer.

Solar thermal panels

The panels generate all the hot water in summer and some in the spring and autumn, reducing the demand on the biomass boiler and the amount of wood used.

Photovoltaic (PV) array

PV panels capture energy from the sun to supply electricity for the whole house.

For Code Level 6, the mandatory heat loss parameter standard is very high placing more demands on the building envelope such as insulation, glazing and shading and how these operate with the technological systems of the house.

Smart Metering and monitoring systems

A Smart Meter records energy consumption, to help occupants identify any wastage and to promote more environmentally aware lifestyles.

Ventilation

Understanding how the ventilation and passive system operates – activated by the ‘windcatcher’ in the Lighthouse.

Heating

The building envelope specification will deliver high levels of thermal insulation and airtightness so that the home will only need to be heated for a couple of months in mid-winter.

Reducing solar gain

External shutters can be used in summer to reduce the build up of heat. They block out all direct sunlight.

Reduced glazing

Complying with the U-values of the Code, the glazing is 5-10% less than that in the traditional home. The living space of the Lighthouse is adapted to accommodate this with a large double height volume on the upper levels with sleeping accommodation below.

Airtightness

Lobby areas design to the front and back

of the house to maintain the high level of the airtightness in the build.

Water

Increased awareness about what water to use where – rainwater for the garden and washing machine, shower and bath water for the WC.

Environmental issues covered by the Code

Environmental Impact Number

Categories of Credits Environmental Weighting Factor (as % of total possible Points Score available)

Category 1 – Energy/CO2 29 credits 36.4%

Category 2 – Water 6 credits 9.0%

Category 3 – Materials 24 credits 7.2%

Category 4 – Surface Water Run-off 4 credits 2.2%

Category 5 – Waste 7 credits 6.4%

Category 6 – Pollution 4 credits 2.8%

Category 7 – Health & Wellbeing 12 credits 14.0%

Category 8 – Management 9 credits 10.0%

Category 9 – Ecology 9 credits 12.0%

Total 104 credits 100.00%

Number of points a house needs to achieve for each Code level

Level 1=36 Points (Mandatory + 33.3 Points)

• Exceeds Regulations

• EcoHomes 2006 Pass

• EST Good Practice

Level 2 = 48 Points • EcoHomes 2006 – Good (Mandatory + 43.0 Points)

Level 3 = 57 Points (Mandatory + 46.7 Points)

• EcoHomes 2006 Very Good

• EST Best Practice

• Conventional Water fittings

Level 4 = 68 Points • Greywater/Rainwater (Mandatory + 54.1 Points) • Passive House (approx)

Level 5 = 84 Points • Zero SAP (Mandatory + 60.1 Points) • Significant Renewables

Level 6 = 90 Points • Zero Operational Carbon (Mandatory + 64.9 Points) • Most Code Credits achieved

For Level 6 – Mandatory issues:

1 Energy Net-Carbon Zero in operation

- Very high building envelope thermal performance

- HLP = 0.8 W/m2K or greater (SAP)

- Renewables for all heating, hot water, lights, fans and pumps.

- Renewables for occupant systems and appliances

- Credits for other low carbon features

2 Water – 80 litres/ day per person of potable water

- On-site water recycling required

- Using new more stringent Water Calculator

3 Environmental Impact of Materials

- Three of five key elements achieve relevant rating of A+ to D

- Update 2007 The Green Guide

4 Surface water run- off

- Peak run-off no greater than existing

- Located in low Flood Risk / Flood mitigation

5 Waste

- Specified minimum household waste handling

- Construction waste management system

Plus 86% of all tradable points

For More Information See – The code for sustainable homes

Top Eco Credentials

1. Air tightness

The most important energy reducing factor. The whole building is airtight.

2. Heat recovery system

An air system changes the air in the property once every two hours, replacing stale, damp air with warm, dry, filtered air.

3. Heat thermal store

Solar panels feed into underground system for year-round energy supply.

4. Low-wattage consumption lighting

LED and low energy lighting throughout. Lighting the garden consumes the same amount of electricity as one traditional light bulb.

5. Rainwater harvesting

Feeds lavatories, washing machines and garden taps.

6. Sewage treatment plant

State-of-the-art system turns sewage into purified water.

Design

Smart and thoughtful design is a crucial first step in building an eco-friendly home. Consider the climate and location of your home. Orienting your home to maximize the benefits of the sun, shade and breeze can save you thousands of pounds in heating and cooling throughout the life of the structure. Likewise, planning for overhangs, rainwater catchment, solar thermal hot water systems, natural light and grey water reuse can ensure your home is as energy- and cost-efficient as possible.

Building Materials

Eco-friendly building materials vary greatly, but they all have resource efficiency in common. These materials may be made from recycled content or harvested from sustainably managed sources. They might be salvaged, refurbished or remanufactured or be reusable, recyclable or more durable than conventional materials. Eco-friendly materials are also manufactured in ways that minimize waste, pollution, greenhouse gases and energy consumption.

Energy Efficiency

Build an energy-efficient home to reduce greenhouse gas emissions, pollution and save money. Effectively insulate and seal your home, including exterior walls, attics and floors. Invest in energy-efficient windows with such features as double panes, protective coatings and improved frames. Purchase efficient and appropriately sized heating, ventilation and air-conditioning systems (HVACs). Look for the Energy rating when purchasing HVACs, home appliances, lighting, water heaters and electronics.

Location Efficiency

Buildings and transportation combined account for about 62 percent of greenhouse gas emissions in the United kingdom. Where you construct your home is as vital to environmental health as how you construct your home. Ideally, it should be located within walking or biking distance to the places you frequent the most, such as work, school, and shopping and recreation areas.

Micro-CHP Explained

Micro-CHP

This a Technology Guide will help to give you an understanding of the technology and application of micro combined heat and power to provide heat and electricity for domestic and small commercial buildings.

This briefing will give the key outline and link you directly to fuller explanations on the internet, and downloadable documents (in case you want to know more about any aspect). Additionally there will be references to key books and pamphlets that can give you better understanding of the subject.

What is ‘Micro Combined Heat and Power’?

Micro Combined Heat and Power (micro-CHP) is a technology that provides an opportunity to use an energy source (normally gas) to effectively produce heat and electricity. Unlike larger CHP systems (mini and full CHP) the application of micro-CHP is typically limited to one property and does not include any need for ‘district’ heating.

Micro-CHP is not classed as a renewable technology (unless fuelled by renewable biofuels) but properly applied it can reduce carbon emissions and total energy costs. CHP is sometimes referred to as ‘cogeneration’.

It will not replace the need for a connection to the mains electrical supply grid but will provide a source of electrical power that can be used directly on the premises or exported back to the grid. The term micro-CHP normally indicates that the output of the system is less than 5kWe (5 kW electrical) combined with a heat output suitable to replace a domestic or small commercial boiler. (This differs slightly from the EC definition of ‘micro-cogeneration’ as being under 50kWe).

Micro-CHP products have been available for some years and the technology is evolving to provide systems that can be included within a domestic or small commercial application that require similar installation and maintenance to that of a gas-fired boiler.

Micro CHP types

There are number of different technologies that can be used for micro-CHP, including stirling engines, rankine engines, internal combustion engines, and fuel cells. Apart from fuel cell technology the systems typically produce 4 to 8 kWth (thermal) heat for each kWe of electricity. If further heat is required (beyond that produced as a result of electrical generation) a supplementary heat exchanger (within the unit) is normally used to supply heat directly to the water for the heating system.

Stirling engines

This is the most prevalent technology in today’s domestic micro-CHP market and the only technology specifically recognised by the MCS.

Unlike the internal combustion engine a stirling engine does not have any combustion process within its reciprocating engine. A sealed cylinder containing a gas (such as helium) is heated at one end by the burning gas and then cooled at the other by the return heating water so that it expands and subsequently contracts and is arranged to actuate a piston to drive an electrical generator. The specific configuration of the engine will depend on the manufacturer but the majority of the moving parts are within a sealed, and so clean environment. The most common application is of the free piston Stirling engine.

The driving heat could be provided by a number of sources including recovered heat and heat from solar sources however in UK micro-CHP applications the energy typically will be produced by burning natural gas.

Since the system relies on heating and cooling process it will take several minutes before electricity is produced whilst it heats up.

Stirling engine micro-CHP typically will convert under 10% of the energy to electricity and the remainder goes to heat. The overall system is likely to be in excess of 90% efficient.

Internal combustion engines

Using well established technology an internal combustion (IC) engine is powered by the expansion of hot gases within the engine. These can be fuelled by petrol, diesel, biofuels, LPG or natural gas and linked in with a generator to produce electricity. Heat is then taken from the engine’s cooling water and exhaust manifold. They can have a higher electrical efficiency than a Stirling engine but are larger and noisier and not commonly applied to the UK domestic market. The practical size range is from less than 1kWe to 5 MWe or more but typically in the UK the size (and noise) have meant that they are more commonly used in larger applications located in plant rooms. Well designed systems can convert 25% of the input energy to electricity.

There is a strong European (and Japanese) market for IC systems that are designed for use both inside and outside domestic or small commercial buildings.

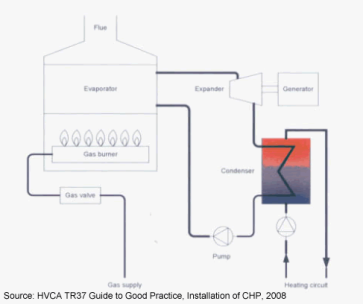

Rankine engine

Rankine engine micro-CHP

These are based on the same concept that drive many large scale power stations that use water in a closed system. Just like the Stirling engine these are driven by heat (normally provided by burning natural gas) that works on a closed system containing an ‘organic’ fluid that requires lower temperatures and pressures than a water based system (using for example silicone oil, or a refrigerant). The fluid is heated to create a gas that is then used to drive a ‘turbine’ that generates electricity – this video shows the technique for a larger system. There are very few of these in the marketplace – see the manufacturer’s site genlec.com for more details.

The Rankine engine has been used to develop systems driven by lower temperature sources potentially for use with waste heat or solar energy.

Fuel cells

A chemical reaction drives a fuel cell where the hydrogen in the natural gas reacts with the oxygen from the air to generate electricity and create heat. Micro-CHP would most likely use solid oxide fuel cells (SOFCs) that consist of a solid electrolyte sandwiched between anode and cathode layers. When natural gas is passed over the anode, it breaks down to release hydrogen. When this combines with oxygen from the cathode, electricity, water and heat are produced – with as much as 80% of the output being electrical.

Current technology means that the cost of fuel cells (both in purchase and operation) is still too high to make them commercially viable for micro-CHP but they potentially offer a noiseless, low emission system with high efficiencies.

A UK company plans to begin wholesale supply of domestic units in 2014 and there is substantial background on fuel-cell applications at UK Hydrogen and Fuel Cell Association.

Micro-CHP units are increasingly designed to take up a similar space to a domestic or small commercial boiler but their current cost (2012) are several times that of a similar output heating only boiler. Their simple external appearance may be deceptive as they will also have more complex controls and mechanisms than a typical condensing boiler.

A recent review including these technologies as applied in Europe can be seen here.

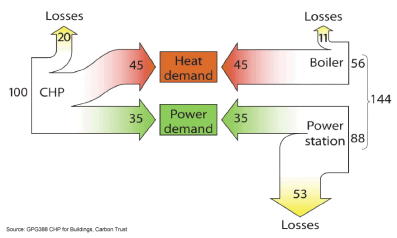

Heat and power from micro-CHP

Micro-CHP consumes the energy source (usually natural gas) at point of use to generate heat and electricity. Grid supplied electricity is likely to be less efficient in converting energy consumed at the power station to electricity supplied to the premises, (probably less than 50% efficient). However CHP can only claim high efficiencies if the heat (produced as a ‘by product’ of electrical generation) is being usefully employed at all times. This can make it difficult to justify CHP where there are low heating demands such as in new, or small domestic premises. Similarly it would not be suitable where there are other renewable heat systems such as solar thermal heating. Due to the laws of thermodynamics the heat efficiency of a micro-CHP will be less that for a heat-only boiler.

A test fuel-cell micro-CHP at the University of Cologne

A test fuel-cell micro-CHP at the University of Cologne

And so currently micro-CHP are designed as ‘heat led’ systems (they operate when there is a demand for heating water) – if fuel cells become more available then ‘power led’ systems (probably linked in with some thermal storage) may become more feasible.

Micro-CHP application

The micro-CHP unit is increasingly designed as a replacement for a domestic or small commercial boiler and has similar requirements for connections to a gas supply and the heating system. There will be additional electrical connection requirements and eventually smart metering will be applied to provide information on the exported electricity. There is a ratio of 1kWh(electricity):6kWh(heat) over the year in the ‘average’ UK home and so the output from an ideal micro-CHP system would match this.

A trial was undertaken by the Carbon Trust (reported on in 2011) of 87 micro-CHP installations in typical UK households and small commercial applications. It found that the larger domestic systems (that used greater than 15,000kWh heating) and small commercial premises were most likely to benefit from savings in carbon. On average small domestic installations benefit (in carbon terms) by a few percent compared to using a condensing boiler and grid electricity.

Micro-CHP functions best with extended operating periods and minimised cycling on and off. For short running cycles (about 1 hour or less) the electricity consumed by the system can reduce, or even eliminate, the benefits. By linking a thermal store into the systems cycling can be reduced and heat can be reserved for use later in the day. The application of low temperature heating systems (such as underfloor heating) can readily utilise heat from thermal stores and can provide lower return water temperatures – this improves the efficiency of Stirling engine micro-CHP.

Under the MCS it is the contractors responsibility to evidence that the micro-CHP is of an appropriate size and design to properly satisfy the system needs of the building.

Planning and Regulation

Requirements for micro-CHP are included in the building regulations and in England this is explained in the DCLG Domestic Building Services Compliance Guide 2010 Edition and also the Non-domestic Edition.

A Sterling engine based micro-CHP

A Sterling engine based micro-CHP

Unlike regular boilers, the performance of micro-CHP systems are not given in terms of a seasonal efficiency (ie SEDBUK) but by the Heating Plant Emission Rate (HPER) for an application in a particular property. The HPER gives an indication of carbon emissions related to the needs of a specific property and is given in kg CO? per kWh. Since the current systems are heat led the HPER is given for each kWh of heat generated (for total heating and hot water), but the carbon value includes that for both heat as well as power generation.

Generally the SAP assessment is used to show compliance in domestic applications. To comply the SAP rating must be acceptable and the system with a micro-CHP should have an improved total rating compared with that of a standard boiler. In existing buildings that are using micro-CHP fuelled by something other than natural gas the HPER must be calculated to be equivalent to a gas boiler of SEDBUK efficiency of 86%. MIS 3007 provides detail of the neccesary calculations to prove compliance for both new and existing buildings.

Under the Microgeneration Certification Scheme (MCS) the Microgeneration Installation Standard: MIS 3007 provides approved guidance on the installation requirements for micro-CHP installations – this is particularly important if government funding is being sought for a project but does, in any case, provide a useful source of information.

For non-domestic buildings the regulations set a minimum Combined Heat and Power Quality Assurance (CHPQA) Quality Index and a minimum electrical power efficiency measured across yearly operation. The CHPQA is based on the ability of a system to be able to produce heat and electrical energy more effectively than using the same fuel in a power station.

Where the micro-CHP operate with other boilers the micro-CHP must be the lead heat generator and normally sized to supply at least 45% of the annual heat requirement. Non-domestic installations must include metering to measure hours run, electricity generated and fuel supplied. The micro-CHP will be included in the overall assessment of the building performance when undertaking the National Calculation Methodology (most likely using SBEM) analysis.

Government Funding

A 15.5kW heat/5.5kW power micro-CHP (1000mm high) with thermal store

A 15.5kW heat/5.5kW power micro-CHP (1000mm high) with thermal store

Gas powered micro-CHP installations are recognised as a small scale low carbon technology by the UK Government. Systems under 2kWe can attract Feed in Tariff payments (FITs) (available for up to the first 30,000 UK installations) for a duration of 10 years – note that there had been fewer than 500 installations by the end of 2011. Systems must be installed under the auspices of the MCS to attract funding and there may be a requirement in future for a dwelling to have an EPC of at least band D to be eligible for FITs.

FITs comprise of 2 elements –

- Generation tariff – a payment for each unit (kWh) of electricity generated. Currently (Feb 2012) this is 11p/kWh but is likely to rise to 12.5p/kWh. The payment is regardless of whether the generated electricity is used in the building or exported back to the grid. To measure the generation there must be an Ofgem approved total generation meter (typically less than £50).

- Export tariff – electricity that is not used on site can be exported back to the grid and a payment is paid as an additional payment (on top of the generation tariff).

If micro-CHP is installed and the property owner/operator receives FITs, and subsequently the property is passed to another owner, the FITs will remain with the installation and accrue to the new owner.

Detailed guidance on the FIT scheme for businesses is available in a clearly written factsheet (CTL110) on the Carbon Trust website

Further reading

Great resources that will provide more detail on the background and application of micro-CHP

References to buy or borrow

CIBSE AM12 ‘Small Scale CHP’ provides a comprehensive reference in the design and application of non-domestic micro-CHP

BSRIA BG 2/2007 ‘CHP for existing buildings: Guidance on design and installation’ does not vcover domestic micro-CHP but does look at how larger CHP can be usefully integrated into systems.

B&ES TR37 – ‘Installation of CHP’ has little specifically on micro-CHP but covers the principles and underlying engine technology as well as much information on good practice when installing and operating larger scale CHP equipment

Web Sites and freely downloadable resources

The Carbon Trust has a whole area developed to the emerging micro-CHP technology that includes downloads of informative resources and also Good Practice Guide 388 – ‘Selecting, installing and operating CHP in buildings – a guide for building services engineers’. They also have a particularly useful guide on FITs for small businesses

Electrical Safety Council’s Connecting a microgeneration system to a domestic or similar electrical installation (in parallel with the mains supply) provides detailed and well written guidance on the considerations required when connecting a micro-chp system.

Energy Saving Trust has a page with up to date guidance and links to appropriate legislation and government web resources

Department of Energy & Climate Change – Micro CHP – A great place to catch up with all the government funding and guidance

Combined Heat & Power Association– A well established trade organisation with some resources mainly looking at larger applications of CHP but still has relevant material that covers the underlying principles and application.

Standards and Regulations

The Microgeneration Installation Standard: MIS 3007 (available at no cost) provides the requirements for installation of micro-CHP to comply with the MCS scheme and provides a reference to other required standards.

The DCLG Domestic Building Services Compliance Guide 2010 Edition and the Non-domestic Edition includes requirements for the performance of micro-CHP systems

Mains Pressure Hot Water Systems explained !

This simple guide is intended to help you understand how mains pressure hot water systems work.

Mains Pressure Hot water Systems – Explained

You may be considering installing new or changing an existing system to provide mains pressure hot water in your home. Generally speaking, mains pressure hot water systems out-perform the more traditional gravity systems by providing higher pressure and flow rates.

A mains pressure system may be an ideal choice for you, but before you make your decision it is prudent to fully understand how these systems work and consider all the facts.

General

The first and most important thing you must understand is a mains pressure system is only as good as the supply entering the property. This is to say, the pressure you perceive at a tap is the product of the water pressure entering the property from the water main. The components and the products attached to a mains pressure system do not in any way enhance the pressure or flow rate that can be achieved at an outlet. For the avoidance of confusion, if your incoming mains water pressure is poor then the pressure at all outlets on that system will be poor.

Example: The product specification of a piece of mains pressure equipment may boast 35 litres per minute flow rate at 3 bar pressure. But if the water main and pipe work to the property can only supply 15 litres at 1 bar then this is all you can expect to receive. Although your mains pressure equipment may be able to handle higher performance it is not capable of increasing the supply pressure or flow. Figures quoted against products are indicative of their potential based on an adequate supply. They are not a definitive statement of what you will get.

How do mains pressure hot water systems work?

| In a property with a mains pressure water system all taps and water outlets will have mains pressure water attached to them – be they hot or cold.

It probably isn’t difficult to understand that all cold taps or cold outlets are connected directly to the incoming water main. Understanding where your hot water comes from takes a little more technical understanding as it is still fed directly from the incoming main but water must pass through equipment designed specifically for heating it at pressure. There are different methods of doing this and many interpretations on product design. Hopefully having read this guide you will possess a better understanding of the various processes and be in a much better position to make an educated choice (negating your risk of dependency on a pushy plumber or the need to trust whatever half-baked nonsense you might be fed!). |

Selecting your hot water system |

Devices that heat mains pressure water differ greatly from more or less all other types of hot water heater. You should never try using a device designed to heat low pressure water (a gravity copper cylinder for example) in a mains pressure system. A low pressure copper cylinder which is typically fed by a cistern in a loft operates under ‘gravity’ pressure (hence the term) which is in effect the weight of water created by the higher position of the cistern. The pressures in a gravity system are typically much lower than those in a mains pressure system. Components designed for use on a gravity system are often manufactured in a manner and from materials incompatible for use with high pressure.

Warning: If you attempt to heat mains pressure water using a cylinder designed for a low pressure system the risk of explosion exists.

The purpose of this article is to describe how water may be heated directly from the main. To be correct one must therefore acknowledge Combination Boilers as these too connect directly to the main and heat water instantaneously. As such, they are regarded as mains pressure devices. We shall not however dwell on this type of unit as they do not deliver the flow rate of a true mains pressure system.

In the field of domestic mains pressure hot water the highest performing systems require a cylinder. It must be note however that the function and purpose of the cylinder may differ according to which system you prefer.

There are essentially two types of mains pressure hot water system –

- Unvented Mains Pressure Systems

- Vented Mains Pressure Systems

The term vented refers to whether the system is partially vented to atmosphere or completely pressurised and therefore unvented. These terms might seem confusing and just a little contradictory so we will try to explain more fully.

Unvented Mains Pressure Systems

In an unvented system, a vessel is filled with cold water directly from the incoming water main. The vessel is kept under pressure from the incoming water supply and heated either by immersion heaters (a direct model) or by a heat source located outside the vessel (an indirect model). Examples of the latter might be a gas boiler, solar energy, and Aga etc. The ‘vessel’ to which we refer normally takes the shape of a cylinder. In an unvented mains pressure system the cylinder must also be regarded as a pressure vessel. This type of cylinder is referred to as ‘an unvented cylinder’ because it is not vented to atmosphere in the same manner as a normal copper cylinder be. Unvented means exactly that.

The unvented cylinder will have pipe work connected to it that will carry the heated contents around the property to various taps and outlets. As soon as an outlet is opened the pressure of the incoming cold water to the cylinder forces(displaces) the contents of the cylinder (hot water) out and towards the open outlet. Hence, hot water is delivered at the tap or outlet at a pressure equivalent to the force of the incoming cold water main to the cylinder.

Unvented hot water cylinders have to withstand considerable internal forces. For this reason most are made from stainless steel (as opposed to copper for a vented/gravity cylinder) utilising the tensile properties of the metal. This is why you should never try pressuring a cylinder unless designed for this purpose. To do so would introduce a very real risk of explosion.

NOTE: Unvented cylinders do represent a risk. Consider… you have a large volume of very hot water in a cylinder under pressure. If the contents of the cylinder were for example to get too hot (because of some system malfunction) the risk exists that the contents of the cylinder could boil, turn to steam and the internal pressure cause structural failure. We are talking about explosion! To combat this issue all unvented cylinders must be fitted with pressure relief equipment that will vent the cylinder in case of such a problem.

To ensure that unvented cylinders are fitted correctly, safely and by competent installers the Government introduced Building Regulations (G3). These Regs cover any vessel that contains more than 15 litres of hot water under pressure.

NEVER attempt to install an unvented cylinder unless you are trained to do so. The consequences could be catastrophic.

If you have any doubts take a look at these:

http://www.youtube.com/watch?v=Cv178a60Ypg&feature=related

http://www.youtube.com/watch?v=iQK6McNdyXE&feature=related

Makes you think… eh?!!

Vented Mains Pressure Systems – Thermal Stores

Having read about unvented hot water systems it might seem somewhat of a contradiction that mains pressure water can be achieved from a vented cylinder – but it can.

They say that the best ideas are the simplest. Well, that could be argued about what’s known as a ‘Thermal Store’.

To the untrained eye a thermal store and an unvented cylinder look very similar. They are typically cylindrical in shape and the are both full of hot water. The difference is how they produce mains pressure hot water.

We have covered the unvented cylinder in the section above. So we shall now focus on the thermal store.

At the outset it must be said that one of the most attractive properties of a thermal store is the fact that it is vented. This is to say that the body (where the great volume of water is stored) is at atmospheric pressure. It is therefore inherently safe as dangerous pressure build up is impossible.

A thermal store is heated is exactly the same way as any other cylinder (directly or indirectly). But unlike nearly all other cylinders the contents (the water) is not destined to appear at any taps or outlets – it is used solely to store a large quantity of thermal energy (a little like the chemicals in a battery store electrical energy).

The way a thermal store achieves mains pressure hot water is by immersing a large heat exchanger in the contents of the store (the hot water) through which cold mains pressure water is allowed to flow. As the cold water travels through the heat exchanger it rapidly becomes hot and exits the cylinder as hot water at mains pressure. Simple!

All the benefits of mains pressure hot water with none of the dangers of unvented.

Thermal stores, apart from being inherently safe, offer several other advantages that are beyond the capability of an unvented cylinder.

- Thermal stores run much hotter than a normal or unvented cylinder (which must be set at the temperature you want water to arrive at taps. So, litre for litre a thermal store holds more energy. Water from a store is governed to a safe temperature by means of an external thermostatic blending valve – ensuring no scalding.

- A thermal store can accept multiple heat sources simultaneously. It can even accept heat from ‘uncontrollable’ heat inputs such as wood burning stoves and Aga’s that typically operate by virtue of gravity (unpumped) circulation.

- A thermal store can be configured at the ‘centre’ of your domestic hot water system taking all sorts of heat inputs (including solar, ground source and air recovery) and giving energy back for domestic hot water, central heating, under floor heating etc. The term is versatile.

- You do not need to notify Building Control when you install a thermal store. G3 Regulations only apply to a vessel containing more than 15 litres of hot water under pressure – the body of a thermal store is vented and there is less that 15 litres of hot water in the heat exchanger. These products do not therefore qualify under these regulations.

- Because there is no inherent danger with a thermal store they may be fitted by a competent person without specialist training. Unvented and vented systems both provide hot water at mains pressure. They achieve this by slightly different methods. There are however certain considerations when choosing the system that suits you best.

Unvented Mains Pressure Systems

- Unvented cylinders provide mains pressure hot water.

- In an unvented system you will be storing a large volume of hot water under pressure. For reasons of safety such systems must be installed by qualified technicians with relevant experience, CITB training and G3 certification.

- As a precaution, pressure-relief pipework and valves must be installed to protect against unsafe pressure build-up within the vessel which could result in explosion.

- Your Local Authority (Building Control Dept) will need to be advised of your intention to install an unvented system.

- For reasons of safety, your system will require annual maintenance to ensure safety equipment is functioning correctly (BS2870).

- An unvented system must be commissioned and certified by the installer.

Vented Mains Pressure Systems

- Thermal stores provide mains pressure hot water

- A vented system does not store a large volume of hot water under pressure. The Thermal Store, whilst containing hot water, remains at atmospheric pressure.

- There are no hazardous issues with a vented system. Pressure relief valves and pipework are not therefore required.

- Vented systems do not require Building Control approval.

- Because of the simplicity and safety of such systems, installers do not need certification or specialist training.

- Vented systems do not need certification.

- There are no special annual maintenance requirements.

enter the realm of mains pressure hot water systems (vented orFirstly, a mains pressure water system is only as good as the supply to the property. Sounds obvious? If your pressure or flow rate (both are very important) are questionable do not proceed. Once you install your system you have what you have and there’s little you can do about it. Be sure you check what pressure you water authority are prepared to guarantee you. Some unvented systems misbehave if the pressure is too low, but then again, why bother if this is the case. A pumped gravity system with all its faults might be better than a poor mains pressure system!

Under water bye-laws you may not add a pump directly to your mains fed system to increase pressure or flow rate. If the supply in your house is poor there will be no simple way to improve it. Additional performance usually entails bringing in a new, larger supply pipe to the property. Even then, you should ensure the new improved supply will be adequate, as some areas suffer from frustratingly low pressure.

Always remember – your system can never be better than the supply to it.

Mains pressure systems are at the mercy of fluctuations in supply pressure. This may not be an issue in the majority of cases.

Mains pressure systems can give ‘power shower’ performance, providing supply flow and pressure is good. If you like a vigorous showering experience and your supply pressure is poor, remember – you cannot install a shower booster pump to improve matters.

Furthermore, mains pressure systems may require you to change your shower valve/s. Because of the likelihood of pressure (and/or temperature) fluctuations in the system you will need to install either ‘pressure balancing’ or ‘thermostatic’ shower valves. Simple ‘manual’ valves can misbehave terribly manifesting huge temperature swings – a very nasty experience!

If you previously had shower booster pumps (either remote or all-in-one) these will have to come out.

Compared – The Good

….and the Not So Good

….and the Not So Good

Unvented mains pressure system

Vented mains pressure system

(Thermal Stores)

Mains pressure hot water to all your taps

Mains pressure hot water to all your taps

No loft tanks – space saving

No loft tanks – space saving

High Pressure storage cylinder

Vented cylinder

External pressure relief pipework required

No risk of pressure build-up

Specialist installation requirements

No special requirements

Annual maintenance required

No special requirements

Notification to Building Control required

No special requirements

-

Recent

- Ground source heat pumps explained

- Fan Coil Units & Air Handling Units

- Mvhr – Comparing energy use and CO2 emissions

- UK – The Code For Sustainable Homes

- The Most Energy Efficient Office Building In The World

- Approved Green Deal Measures

- Global Sustainable Building

- Fighting Mould & Condensation In The Home

- Popular MVHR systems set to tackle efficiency targets !

- Top Eco Credentials

- Heat recovery – the debate continues

- Demand controlled ventilation (DCV) for better IAQ and Energy Efficiency

-

Links